For customers

If you have any idea for a new device powered by electricity, we will design the best electric harness for you:

- Based on your documentation (connection map, 3D model), we will design cable connections and propose possible changes to the connection map;

- We will select the components needed to make the harnesses;

- We will prepare 2D and 3D documentation of the harnesses assemble.

If you have a ready design and are looking for a new supplier, or would like to check out an alternative offer, we can provide:

- Support with starting production and optimizing the supply chain;

- Shorter delivery dates;

- Faultless quality and cost-cutting;

- Product reengineering.

If you are launching a new project:

- We will give you a quote on a wire harness – we always look for the solutions that benefit you the most, assuming that quality comes first and savings are a norm;

- We will look for possible savings at

– the design stage of the harness (if you order the design from us)

– the selection of components (if you’re sending your own design)

– the prototype stage – we verify the compliance of your designs

– serial production stage – by introducing automated solutions - We ensure quality at every stage of production design and manufacturing of the wire harness;

- We guarantee support for your supply chain;

- We act as an external R&D for our client companies.

Quality is the reference point at every stage of our works, we continuously work to improve it, this is self-evident in our flexibility and friendly service.

Would you like to learn about our leading technologies?

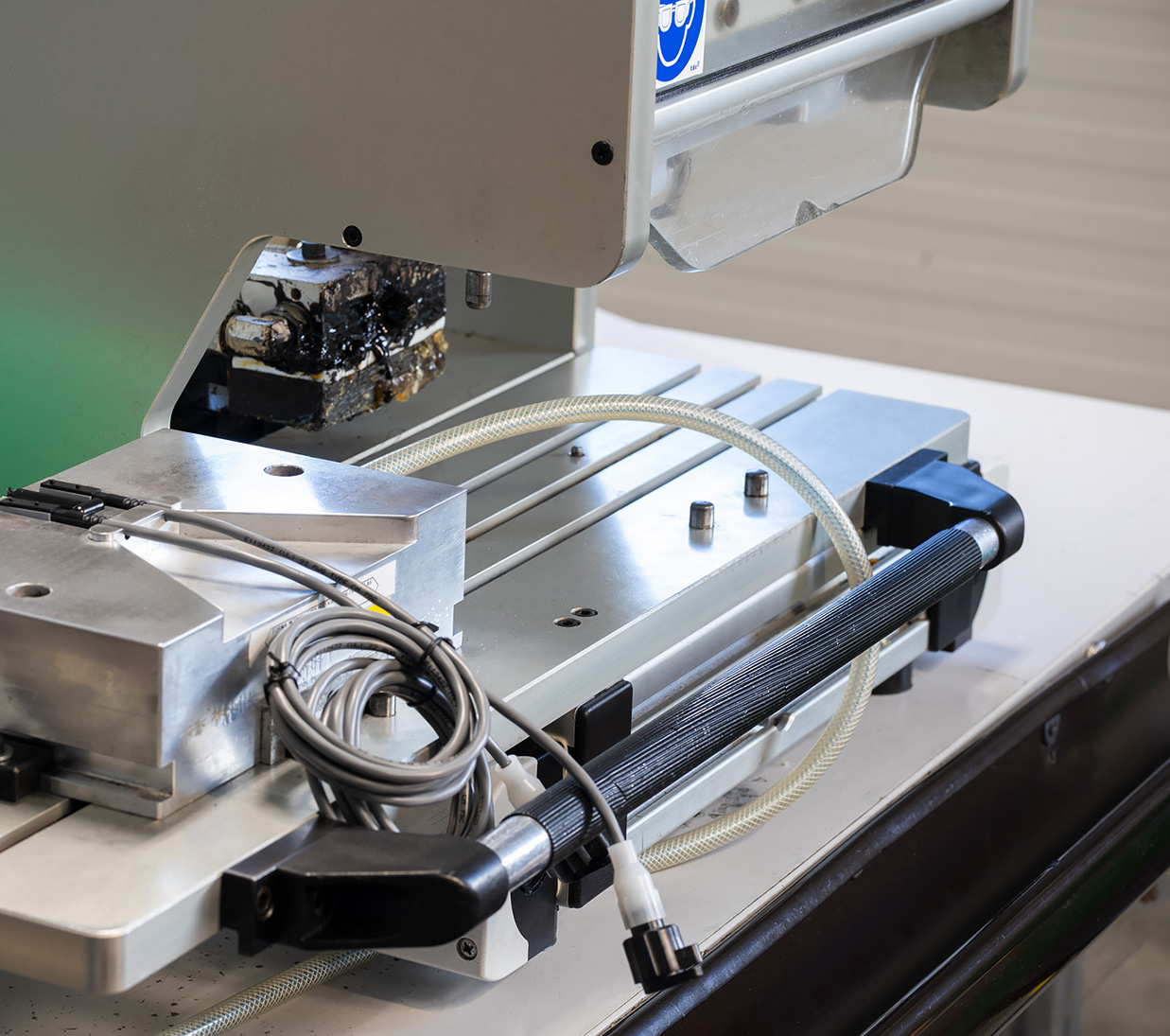

Wire harnesses

We offer designing and production of electrical harnesses, both simple solutions comprising single cables and multi-cable arrangements for installation on dedicated panels. We prepare the harnesses assembly process individually for each client. We carry out prototype and serial projects.

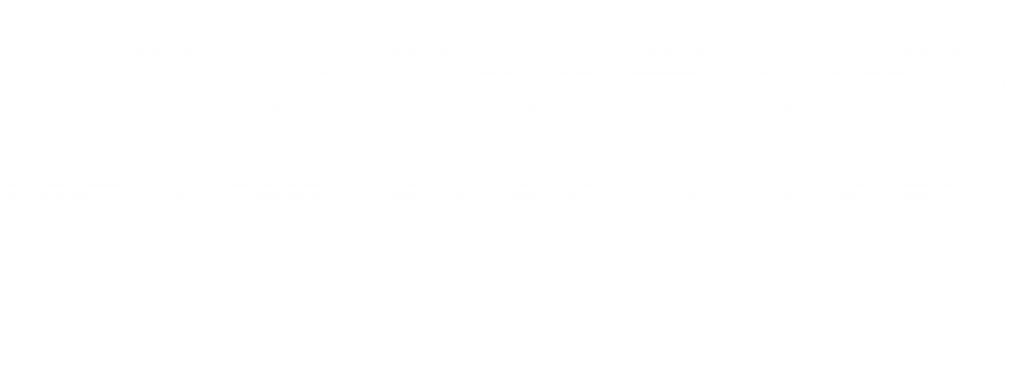

Low pressure molding

Our machine park includes low pressure injection molding machines and resin casting stations. We perform injection under pressure in the range from 0 to 40 bar, guaranteeing protection against damage to delicate electronic components.

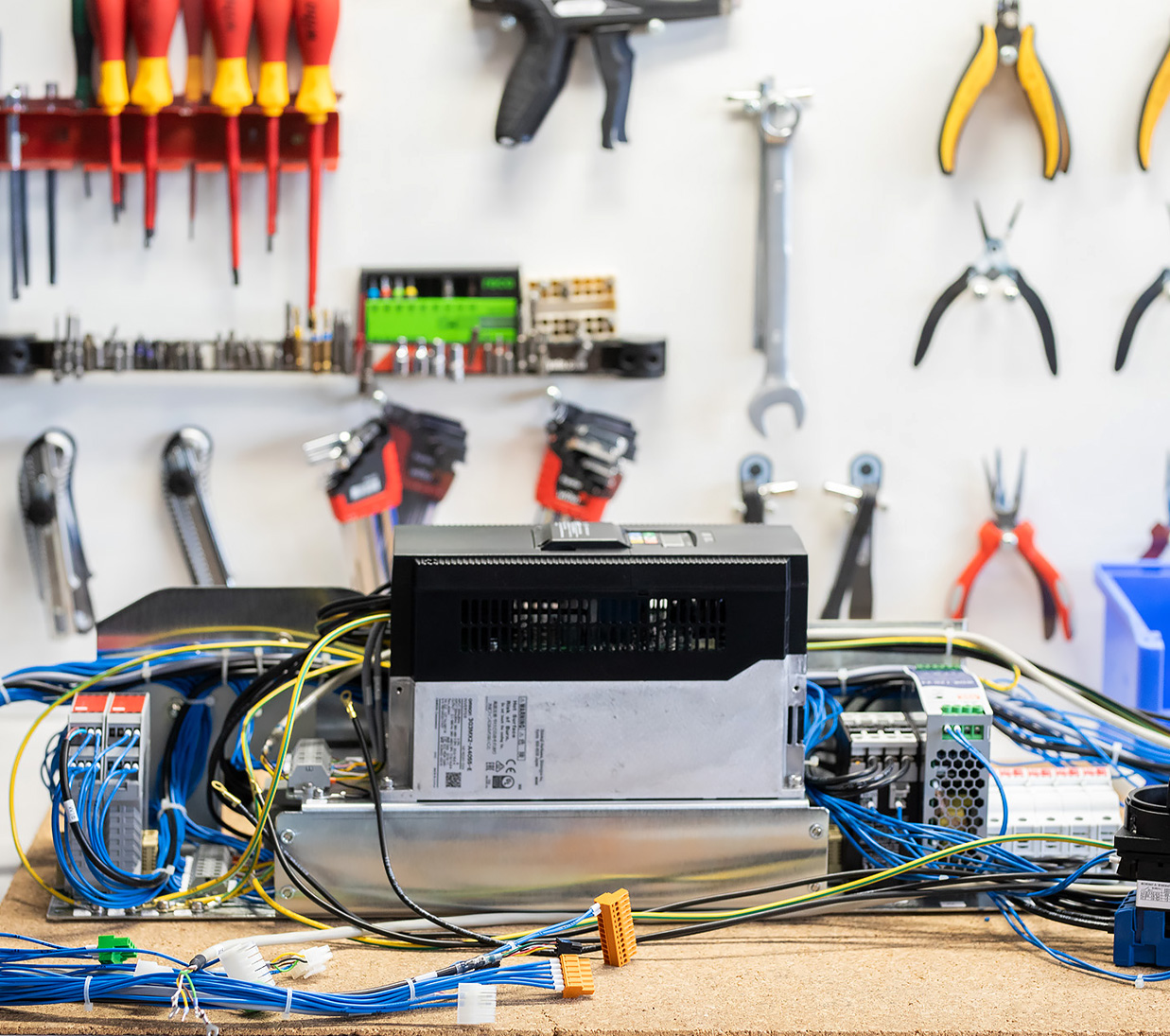

Cabinets and equipment

We offer assembly of complete control cabinets and electrical equipment based on the customer’s design. We provide the entire supply chain, including custom-made components.

EPA protection zone

We have an Electrostatic Protected Area. Thanks to this, we guarantee the safety of the production of electronic components susceptible to electrostatic discharge (ESD).

Manufacturing lines

Our in-house R&D builds dedicated manufacturing lines and machines to improve the assembly processes and guarantee top quality and productivity.